CRYSTAL converts thin film structures to processes for Inficon IC/4+, IC/5, IC6 deposition controllers. Processes are uploaded via RS-232 or LAN interfaces.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

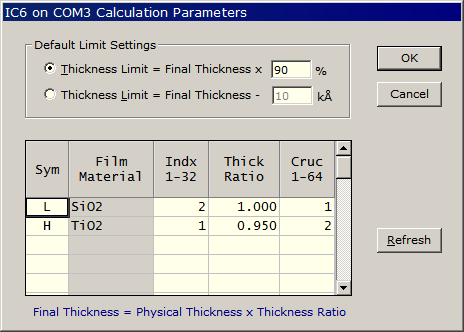

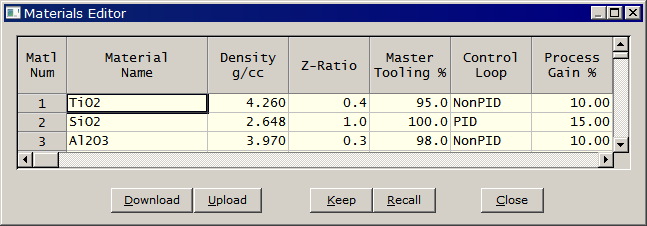

Calculation ParametersFilm Indices and Calculation Parameters

appropriate for the specified controller are stored as Parameters files. Typically each

coating chamber has its own file. Film designs generated by FilmStar

DESIGN may be loaded from disk or pasted from the Windows clipboard. While designs can

also be edited in CRYSTAL, this feature can be disabled for security. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

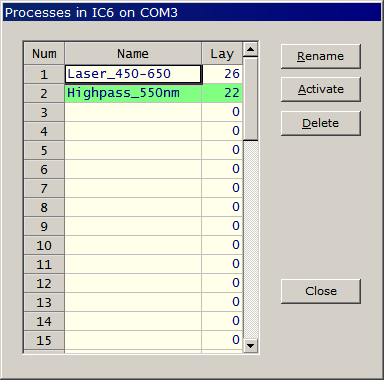

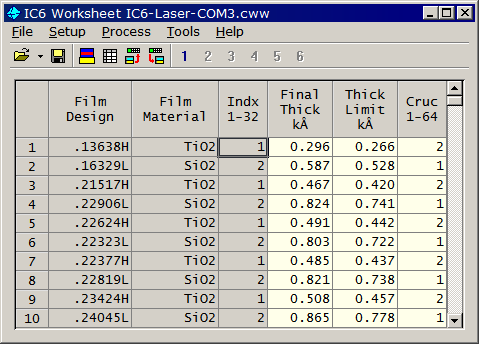

CRYSTAL WorksheetGenerated for each instrument. These may be loaded from disk, calculated from a thin film design, manually edited, uploaded to the deposition controller, downloaded from the controller, and stored on disk. Worksheets can be modified with FilmStar BASIC or transferred to any Windows spreadsheet. Thickness settings can be automatically adjusted to compensate for nonlinearities. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Custom Monitoring SoftwareFTG Software can provide custom monitoring software for special purposes. The accompanying image displays program OxLoad which generates binary coating recipe files on disk for an Oxford Instruments coating chamber. Previously the user spent hours typing recipe files. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||