|

The FilmStar Workbook is a spreadsheet

module built into DESIGN and

MEASURE. Utilizing familiar spreadsheet syntax, it provides a powerful

programmable interface for analyzing and optimizing spectral response.

|

|

FilmStar Workbook for

Average/Maximum %T & %R

On-line Function Reference

|

Introducing the Workbook

Once a spectrum is calculated or scanned a single click or keyboard

shortcut pops-up the workbook and

transfers the new spectrum. Multiple spectra can be inserted into adjacent columns.

Formulas are virtually identical to those in Microsoft Excel.

Since the workbook includes macro capabilities, it can serve as an

alternative FilmStar front end with the spreadsheet paradigm replacing

the normal spectral plot. This is useful for evaluating and optimizing

coatings when integrated performance is defined without reference to a

particular spectral shape.

|

|

Optimization using Generalized

Merit Function and Constraints

(4 layer AR with unusual

thickness constraints)

|

Optimization in DESIGN

Supplementing DESIGN's traditional optimization target list, FilmStar

supports generalized merit functions and constraints for meeting system performance

requirements. Constraints such as total layer

thickness or stress can be included. These capabilities are not available in

other optical thin film software.

Essentially, a spreadsheet cell is treated as a merit

function and a group of cells defines constraints. Since these cells can be general

functions of multiple spectra and/or layer thickness there are many options.

Most importantly for active devices such as solar cells, integrated absorption

in specified layers can be optimized.

|

|

5% Coating Errors

(but what's the % yield?)

|

Tolerancing

uses Monte Carlo techniques to estimate coating yields. Graphically, errors affects

coating performance as shown here.

But we don't know the yield from looking at the graph. Workbook tolerancing provides a way to estimate yields. The

workbook is set up so that named cell Passed

($E$9)

has value TRUE or

FALSE depending on

whether the coating passes or fails the specification. Assuming that the average cannot

exceed 0.5% over the range 450-750 nm and the maximum cannot exceed 1%, the following

formulas are all that is required:

$E$9 =AND($E$5<0.5,$E$6<1)

$E$5 =100*AVERAGE($B$5:$B$35)

$E$6 =100*MAX($B$5:$B$35)

Here's the results (100 iterations at each error level):

2% -> 100% yield

4% -> 73%

6% -> 51%

etc.

Tolerancing can also be performed under FilmStar BASIC control. This

might be appropriate when independent layer errors are insufficient to describe the

situation or when pass/fail criteria are exceedingly complex.

|

|

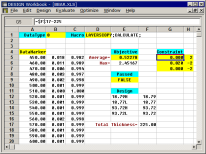

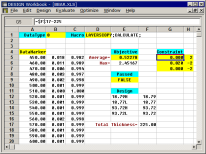

Quality Control Calculation

|

Quality Control in MEASURE

The MEASURE workbook is virtually

identical to the one in DESIGN and shares the same source code. The model shown

here is

used in the example in the Report Generator page.

Essentially, the same workbook model used for design tolerancing is used for quality

control. The only difference is that a pass/fail label like MEETS specifications

is generated instead of percent yield.

|