|

Technical Issues - Si3N4 Case Studies Single Layer: A scientific research organization, herein

designated Laboratory, needs to characterize films

deposited on Si. Being new to FilmStar they provided us with

reflectance spectra for analysis.

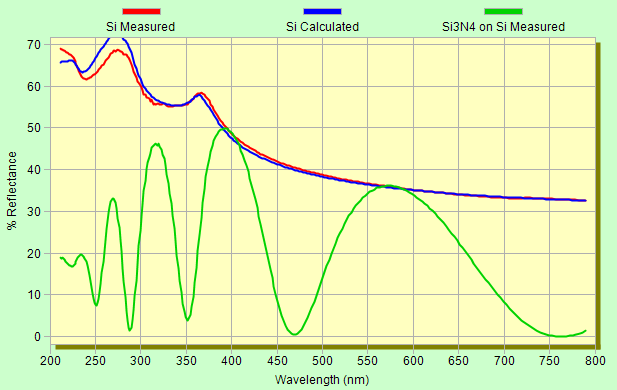

We next evaluate with published Si3N4 n,k data (Filmetrics), and use the Interactor to compare and deduce thickness. As shown below, Laboratory UV absorption is far greater than predicted. In general one needs %R and %T data to compute n&k. But in general also implies not always. (%T is normally sufficient for oxides.) While max and min %R values deviate greatly, wavelengths coincide quote well.

Therefore, to a good approximation, we are able to deduce k without %T data. In the User Index Function shown below, n = Table 1 (Si3N4_Filmetrics.itw) and k is given by a Cauchy formula.

The Interactor (Compare mode) is then applied to the job of deducing thickness and index coefficients. The green curve is measured data while the red curve is calculated. We were getting closer!

Dispersion is adjusted in Setup..Adjust Indices <Ctrl+A>. With only 3 coefficients it is easy to manually arrive at approximate values which are then further refined via DLS optimization.

Recalculating after DLS refinement gives the following.

We next transfer the User Index Function to program INDEX to verify that the dispersion curve appears reasonable. The function is copied from DESIGN's Film Indices dialog via Edit..Copy Function

and transferred to INDEX's Index Functions dialog via Edit..Paste Function.

As we see below, the Laboratory film is very absorbing. Luke and Philipp data were downloaded from RefractiveIndex.Info wherein references can be found.

More about User Index Functions: CEC systems, Double Dispersion, Leybold Monitoring Report. Multilayer Analysis with Global Search: Following our analysis of Si3N4 deposited on Si, we analyzed spectra corresponding to layers of SiO2, Si and Si3N4 deposited on Si. As no information was provided as to the approximate thicknesses of the three layers, we utilized Global Search to find a reasonable starting design for DLS or L-M refinement.

At this point, we were able to deduce layer thicknesses as shown below.

A further step added $SI3N4K refinement to layer refinement. While this reduced the merit function, it gave unreasonable results (not surprising). The Laboratory would do well to add %T measurements, say Si3N4 on fused silica. There is only so much one can learn about n&k with only %R measurements at 0°. At this point we wait to hear from the Laboratory as to whether our solution is reasonable. |

Copyright © 2023 FTG Software Associates

Last updated on

January 31, 2023