|

ZOOM

|

We use ZOOM to display our screen.

We

can view your screen when you give permission. |

|

|

FlexiHub enables

us to control remote instruments connected to USB or serial

ports. Your COM1 becomes our virtual COM1, etc. This

powerful facility eliminates expensive on-site visits. |

|

Installation

& Startup

Backing up data files

Gdiplus.dll not found

Installation/USB key

problems

Invalid license type error

License key exchange

Mcary5.exe

installation issues

Multiple

instances (sessions)

OLE2.DLL

is not a valid Windows image

P-E Lambda 19

installation

Transferring

FilmStar

to new computer

Updating USB License Keys

Unexpected error;quitting

Windows

7 (Vista) compatibility

Windows

Remote

Desktop

Input/Output

Black

scroll bars

Dialogs off-screen, possible freeze

File open/save options

File List Dialogs

File Properties

(NTFS)

Grid keyboard shortcuts,

etc.

Organizing data

directories

Graphics

FSPlot

bitmap/gradient modes

Bold fonts don't look good?

Comparing

%R and

%T spectra

Changing axes

quickly

Diabatic

transmittance

scale

FilmStar dialog fonts

Font size

multiplier

FSPlot 5.0 to 6.0 update

FSPlot Customizer

FSPlot Tutorial I - Appearance

FSPlot Tutorial II - Legends

FSPlot Tutorial III -

Annotations

FSPlot Tutorial IV - Formulator

Modifying

FSPlot legends

Mouse pointer

disappears

Multiple

spectra in

FSPlot

PowerPoint

presentations

Size

of Print Graphics

printout

General

Configuration not

saved

FilmStar

Administrator

Importing illuminants

Reporting problems to

FTG

Software

Subscript out of range error

BASIC,

Excel, etc.

Aborting a

BASIC program

Adding audio

to

BASIC

Bandwidth

calculations NO VBA

C++

How-to

Converting spectral

data I

Converting spectral

data II

DDE (dynamic data

exchange)

DDE / BASIC / Excel

Deleting rows in

Excel

Embed BASIC in

MEASURE, Scantraq

Excel (as client)

reliability

Excel

DDE doesn't work!!

Excel

XLSM file doesn't work

Excel VBA dialogs in

BASIC

Excel VBA issues

FilmStar and Excel

FilmStar class references

Getting

started with MS Office

Laser Focus World April 2014

Saving multiple spectra

OCX in BASIC?

BASIC Tutorial I -

Getting

Started

BASIC Tutorial II -

Advanced

BASIC Tutorial III - Examples

Saving Excel data without the

macros

Saving tolerancing data in Excel

VBA, FilmStar objects &

processes

MEASURE/Scantraq

ActiveX servers

Agilent Cary

UMA/UMS

Agilent/HP 8453 setup

Angular dispersion

AR reflectance setup

Automating

measurements (PDF)

Bandpass Calculator

BASIC FileSave bug

Cary UMA doesn't connect

Cary UMA

Support

CIE Color with diode-array

COM port in Windows

7 XP Mode

Configuration bug

Eliminating Side 2

Reflectance

Embedding BASIC code

FTIR stability

Function FileOpen disabled

error message

Global COM port

change

Identifying bad data

Illuminants editor

Import PE spectra

(.sp)

Lambda 2 (10/12/14)

cable

Lambda 19

installation

Lambda

20/40

timeout error

Lambda

800/900 common beam filters

Lambda Error

-241 (Missing hardware)

Lambda Bio/XLS

installation (Scantraq)

Lambda Server error (950/1050)

Log files

Mcary5.exe

installation issues

Nicolet (Thermo

Scientific) FTIR support

Noise issues

Ocean Optics support

OLIS Excel spectra

OLIS Upcycled 983

OMT Solutions

PE ARTA/TAMS support

PE spectrophotometer

communicating?

PE Spectrum 10

(FTIR) support

PE

Spectrum 10 sample files

Photon RT (Essent

Optics) support

PIKE autosampler support

Plotting multiple

spectra

Problem with %R

baseline scan

Saving multiple spectra

Saving spectra in two file formats

Scan macros

Scan vs. time

Spectra Collector

Spectrum GX/2000

setup

Spectra vs. temperature

Standard files

Startup Method

StellarNet Support

Time Series

Too many points in Standard file

Unsupported

instruments

Wavelength

calibration

Wavelength

List Generator

Report

Generator

Graph not displayed

Including date/time

in report

Report Organizer

Tutorial I - Getting Started

Tutorial II - Advanced

Tutorial III - MS Word

|

DESIGN

Absorptance in

layers

AI replacing coating engineers?

Air and substrate

'layers'

AR at all wavelengths (unobtainium)

AR for two

substrates

Bandwidth compensation

for R/T vs. t

BASIC

Function Calculate

Bruggeman step by

step

Changing plot

type

quickly

Collector to targets

Coating both sides

Color Matching

Combining

multiple

designs

Contour data

import/export

Contour plots

Correcting

measured spectra

Correcting thickness

errors

Cutting Edge

Coatings

DLS

'ActiveX component...' error

Design Recorder

Designing

for

FWD and REV incidence

Designs

don't work on new computer

Double Dispersion

Edge filter

performance

Electric field

algorithm

Eliminating Side 2

Reflectance

Ellipsometric plots

Ellipsometry when k~0

Encrypting designs

Extended materials

Flip Fixture

Optical Monitoring

Flip-flop example

Gedankenspektrum

Methods (PDF)

HunterLab spectra

import

Illuminants editor

Index as a function of

thickness

Index fitting with $NK

Index Formulator

Index Limits

Index temperature

dependence

Index vs.

wavelength

Index tolerancing

Index variations in

layers

Index variations (My

TiO2)

IndexSolve.bas

video

IndexSolveCL.bas

update

Interactor custom

plot

Interactor monitor

spectra

Interactor

Smith chart module

L*a*b* tolerancing

Layer Error Analyzer

MacAdam ellipses

Many layers

Many materials

MCalc: import designs

Minus filter

designs

Mixed materials

Multiple substrates

Non-uniform coatings

Optimizing two

designs

Optimizing

phase shift

Overflow error

Phase plots

Photon RT (Essent

Optics) support

Photopic response

curves

Piecewise n&k determination #1

Piecewise n&k

determination #2

Plotting Fwd and Rev

reflectance

Plotting multiple

spectra

Reflectance vs.

thickness and wavelength

RGB Comparator

Reliability of

inverse-synthesis

Rugate analysis

Saving Tolerancing

Data in Excel

Spectra Collector

Stack Mode

Target Generator

TFCalc: import

designs

Thickness profile

THK variables

Tolerancing

Tolerancing

algorithm

Tooling factor

correction

Tooling factor global

search

User-defined

functions

Veeco Spector OMS

support

Wedged substrates

When is a layer massive?

ZEMAX

coating files

INDEX

Alloys (AlGaAs) and mixed materials

Ambiguity in n,k

for single films

Bruggeman approximation

Extract n,k from

graphs

Double Dispersion

'Film Only' Absorbance?

Group Velocity

Dispersion (GVD)

Import MCalc

materials

Import n,k Tables and Functions

Import Excel n,k

tables

Index as a function of

thickness

Index fitting with $NK

Index Formulator

Index Functions updated

Index variations (My TiO2)

IndexSolve.bas video

IndexSolveCL.bas

update

Invalid procedure call or

argument

Lorentzian dispersion

revisited

Merge R & T spectra

n&k for Films on metallic

substrates

n&k Oxides Step by Step

Optical glass (Schott,

Ohara, etc)

Piecewise n&k determination #1

Piecewise n&k

determination #2

Plotting index

functions

RefractiveIndex.INFO

Refractive index data (Luxpop)

Schott filter glass

database

Si3N4 case study

Solving for k with

known n

Sopra database of optical indices

Determining k in filter glasses

Temperature dependence

TFCalc: import materials

Wavelength

List Generator

ZrO2 case study (inhomogeneity)

MONITOR

Coating run-time

Combining layers

Intellemetrics FilmMaker

FilmMaker

material properties

Glitch at company X

Leybold Monitoring Report

Monochromator

bandwidth

Veeco Spector OMS

support

Wavelength

calibration

FilmStar

Database

Accessing

the database

Adding Scan command

to database

Connecting to

enterprise

databases

Database

capacity

Design value list in

Spectra database

FileMaker spectra

database example

FilmStar

Workbook

Hidden

Workbook

Saving multiple spectra

Tutorial I - Getting Started

Tutorial II - Multiple Spectra

Tutorial III - Constraints

|

|

|

|

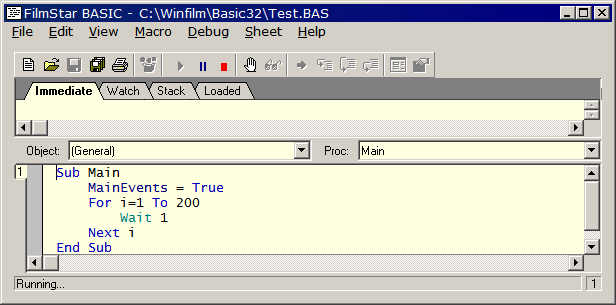

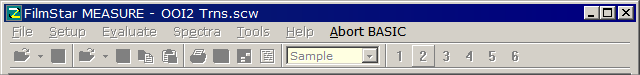

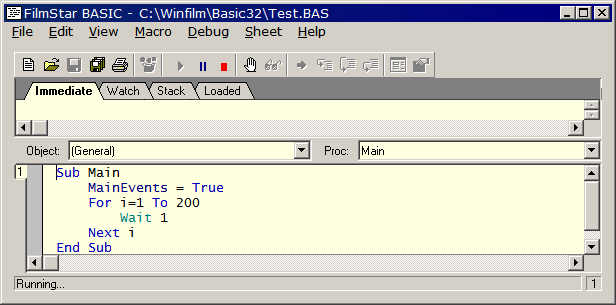

When running a BASIC program

from the IDE (editor) it's easy to quit: just click the red

END icon.

When running from a macro

button add line MainEvents = True to enable the Abort BASIC

menu command shown below. This works in all FTG Software programs.

While this capability has

been available for some time (DESIGN 2.30.1305 and MEASURE (Scantraq)

2.30.1101) we thought it was too easy to inadvertently stop a lengthy

macro (e.g. multiple spectra measured over a wide temperature

range). This issue has been addressed in DESIGN 2.61.3052, and

MEASURE (Scantraq) 2.51.1347 with a new confirmation dialog: click

Yes to quit BASIC or No (default) to continue. Note that

quitting may not be immediate.

Back

to top

FilmStar DESIGN

calculates absorptance vs. wavelength and absorptance vs. thickness

(differential absorptance) for specified layers. While most designers

never use these

capabilities, they are important for solar cells and other active

devices. Calculations

can also be applied to the design of laser-resistant coatings. Note that Side 2

Compensation = FWD ignore/include Side 2.

Sample file absorp.zip

contains FILM Archives

absorp1.faw & absorp2.faw, Excel 97 model absorp.xls and DESIGN

Workbook absorp.vts.

Integrating differential absorptance over layer thickness gives total

absorptance for each

layer at the specified wavelength. (This corrects a previous definition

where results were

normalized by total absorptance.) Methods for verifying results are

given here.

Back to top

Using ActiveX server

audio.exe based on

Microsoft library mci32.ocx, it is

very easy to add audio to FilmStar (Scantraq) BASIC programs. A typical

application is informing QC technicians when a scan is completed. A

sample BASIC

program plus support files are provided in audio.zip.

Back

to top

Need to optimize a

coating for two substrates?

This can be accomplished by

changing the substrate index during each iteration. An example is given

in bbar2sub.zip.

Copy the .bas files to c:\winfilm\basic32; copy bbar.faw file

to

c:\winfilm\designs; copy bbar2sub.xls to c:\winfilm\workbook.

Open FILM

Archive bbar and click Evaluate...

Workbook (<F3>)

to

activate the FilmStar Workbook. Close any open worksheets and open

bbar2sub.xls.

Just click Optimize... Optimize

(<Ctrl+O>)

to proceed. Back

to top

A UK user reported that grid scroll

bars in dialogs such as the Data Table (<F8>) sometimes turn black

thereby making scrolling inconvenient. We were not able to reproduce

this error, but the user reported that our suggested fix solved the

problem:

File...

Configuration... Preferences... <Grid Style>... Grid... Type... Classic.

Back

to top

Thanks to Charles

Anderson at St Gobain for supplying the following

step-by-step tutorial on utilizing FilmStar as an automation server for

applications developed in C++.

It is very easy to

create an MFC automation C++ client that uses FilmStar

DESIGN (MEASURE) as an automation server. To do this :

- Using Visual C++

Studio create a new MFC application using MFC AppWizard (.exe). In step

3 check the Automation checkbox.

- With the Class Wizard

create a new class. That is, select the "Add Class" button and

afterwards select "From a type Library". A file selection dialog box

appears. Files appear withe the extensions "tlb olb and dll". However,

change this to all files and go to the Winfilm folder. Select the

Design1_32.exe file and select the Open button. A Confirm Classes

dialog appears with _clsMain and _clsBasic as the new C++ classes and

Design1_32.cpp and Design1_32.h as the files that will implement the

classes. Select the OK button and the classes are created.

- To use the classes

somewhere in the application create instances of the new classes. That

is add the lines :

_clsBasic

filmStarInterface;

_clsMain filmStarProgram;

For the _clsBasic

class (the _clsMain is the same) add the lines

if

(filmStarInterface.CreateDispatch(_T("FtgDesign1.clsBasic")))

{

// success

}

else

{

// problem

}

Note that automation

ProgID is called "FtgDesign.clsBasic". The

program is now ready to call the methods such as with the lines :

CString

m_design("4G 40M");

filmStarInterface.SetAngle(

60.0);

filmStarInterface.SetDesign(m_design);

filmStarInterface.Calculate();

filmStarInterface.DataCopy();

That is all there is

to it. Back

to top

Cary UMA doesn't connect

Even though MEASURE is not visible,

it is possible that a previous instance of Mcary5U.exe was not

terminated and has not released the Cary driver. In that case you

can open Task Manager and delete spurious copies of Mcary5U.exe

under Processes.

Quick alternative: Download

KillMcary5U.exe to your desktop. This deletes one or more

instances.

Coating

both sides

Users familiar with other software might erroneously conclude that DESIGN does not have a way to input

Side 1 and Side 2 layers. Instead, DESIGN offers the more powerful

capability of treating substrates as Massive Layers, thereby

allowing multiple substrates with films on some or all sides. Referring to

Setup.. Film Indices, entrance medium AIR is 1.0 and exit

medium SUB 1.0.

Combining

layers in MONITOR

When importing a design containing

parentheses, MONITOR expands groups and combines layers of the same

type: '1H 1H' -> '2H'. In some cases you don't want that to happen.

To prevent combining, before saving in DESIGN, expand the design in

the Layers Editor with 'Edit.. Combine Layers' UNCHECKED. Then save

the design or FILM Archive for loading into MONITOR.

Configuration not

saved

Your computer does not

retain capacity settings, preferences or file locations? Probably you

are in an organization with overly restrictive IT policies.

File.. Configuration

entries are stored in *.ini files in C:\Winfilm\Config or

C:\Scantraq\Config. These are sometimes not saved because users do not

have appropriate permissions. The problem can be seen by right-clicking

on an .ini file name in Explorer and examining Properties.. Security.

If it is not possible to edit Permissions and add Write, contact your

IT manager to fix the issue. We suggest that you also demand full

rights to update (reinstall) FTG programs.

FilmStar MEASURE

performs the following calculation in order to correct raw

spectrophotometer measurements.

Standard * (Sample -

Baseline)/(Reference - Baseline)

With a modern

instrument where the baseline is reliably zero, this calculation is not

normally required in transmission. It is, however, required in

reflection measurements.

Hitachi and Shimadzu users who cannot use MEASURE can perform similar

calculations in DESIGN on imported spectra. While the calculation is

readily performed in FilmStar BASIC, you can also use the FSPlot

Formulator to evaluate a formula over an entire spectral range. The

process goes like this:

a. Import measurements

and convert to the same wavelength range by using Sub DataConvert.

b. Use the FSPlot Formulator to correct the spectrum. Assuming that

Baseline data is in column B, Reference data in column C, Sample data

in Column D and Standard in Column E, the corrected spectrum is given

by the following formula. Once everything is set up correctly, pressing

<F9> runs the formula without showing the formula editor.

F =

E*(D-B)/(C-B);del B;del B;del B;del B

c. After

inspecting the plot, click

Edit...Copy Data to copy a corrected spectrum to the clipboard. (The

"del" commands remove unwanted columns C-F.) Warning: a spectrum

will be clipped if the data goes above or below graph limits. Try -10

to 110 to make certain that clipping is avoided.

A BASIC

macro encapsulating the above steps is easily developed. BASIC

Sub PlotDataCopy

copies FSPlot spectra to the clipboard. Back to

top

Suppose you have a

column of data, say a spectral weighting function, corresponding to a 1

nm interval. You want to copy and paste this into a FilmStar Workbook

model, but prefer to convert it to a 2 nm interval in order to speed up

calculations. This task is readily accomplished with the following

Excel VBA program:

' Excel VBA code

to delete every other line beginning at StartRow

Const StartRow = 4 ' starting row number

Sub Main()

Dim s$, i&

i = StartRow

Do Until Cells(i, 1) = ""

If Val(Cells(i, 1)) Mod 2 = 1 Then Cells(i, 1).EntireRow.Delete

i = i + 1

Loop

End Sub

If you use the macro recorder to

clear a spectral range, it only applies to a range of the same size

and position. The following shows a more general way to clear a

range; you only need to specify the upper left cell location ULeft$,

for example "$A2".

Sub ClearList(Byval Sheet$,

Byval ULeft$)

On Error Resume Next

Sheets(Sheet$).Select: Range(ULeft$).Select

Range(Selection, Selection.End(xlToRight)).Select

Range(Selection, Selection.End(xlDown)).Select

Selection.ClearContents

End Sub

Back

to

top

This error typically

occurs after installing FilmStar on a new computer and copying

previous designs and data files. The problem is that settings in

c:\winfilm\config\design1.ini were not transferred.

- Check directories in

File...Configuration...Directories.

- Check values in

File...Configuration...Capacity. It is possible that previous data

files expect larger data arrays than currently allowed.

- Check entries in User

Index Functions, Macros, and the Workbook.

A convenient procedure

is to save the original design1.ini

(measure.ini, scantraq.ini) to floppy or USB stick on the original

machine and copy it to the new machine. Then, if the FilmStar data

directories on the new machine are different from the original, open

design1.ini in Notepad and modify paths via global search and replace. Back to

top

|

FIXED 13

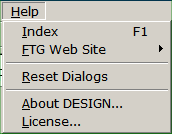

Sep 18...Off-screen dialogs are automatically reset.

FilmStar saves size and

position settings for several dialogs. This can lead to

off-screen windows and freezes when, for example, disconnecting a laptop

from a higher resolution monitor. Actually the program

is still active and

the dialog can usually be closed with <Esc> or <Alt+C>.

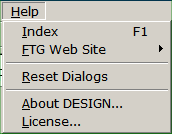

Click Help...Reset Dialogs.

Should that fail use Task Manager or

EndFTGprocs to end processes and open

..\Winfilm\Config\Design1.ini in Notepad. Delete window

coordinate lines under [Configuration], and save. Example:

TargetsWindow=0

9547 5445 29690 27080 0 0

Upon restarting DESIGN,

dialogs are reset. Windows

coordinates are also in [MONITOR], [CRYSTAL], and [INDEX]

sections in Design1.ini as well as Measure.ini. Hint:

Click Reset Dialogs before disconnecting a laptop from a

high resolution monitor. |

|

Yes it does! DDE

requires brackets around commands. Otherwise the system hangs up. VBA

format should be as follows:

Sub Main()

ch& = DDEInitiate("DESIGN1", "Main")

DDEExecute ch&, "[Fred;]"

DDETerminate ch&

End Sub

Names used in DDEInitiate are as

follows: DESIGN1, MPE983,

MPE19AX, MHP8453, MH3410, MCARY5, MCARY5U, MPE950, MPE1050.

Click here for

information about DDE with FileMaker. Back

to top

We were puzzled when an Excel XLS

workbook was saved as XLSM and failed to work. An example can be

found here.

We assumed it had to do with ActiveX

communication, but the Excel bug revealed itself as

something else. Saving RunDESIGN97.xls as RunDESIGN97.xlsm changed

button names from cmdCalculate and cmdQuit to

ButtonCommand1 and ButtonCommand2.

With hundreds of

millions of users, we wonder how an obvious bug like this wasn't

fixed. (We were using Excel 2010 and it is possible that the bug was

fixed later.) Note that RunDESIGN2007.xlsm illustrates a different

approach for connecting with DESIGN.

Note added March

2012: Users with many materials

should use Stack Mode

instead of Extended Materials.

Setting

Film Indices (in File

Configuration Capacity) to a number n > 52

places DESIGN into Extended

Materials mode. Since

designs in this mode are

incompatible with normal designs, the facility should only be utilized

if more

than 52 materials are actually required in one design! In

normal

operation, letters A-Z (+ a-z when n > 26) indicate film

materials. When n

> 52, letters are replaced by numbers enclosed in square

brackets with the

numbers corresponding to those in the Film Indices editor. That is,

.06502H .08876L

.53248H .25093L

is replaced

(replacement is NOT automatic) by

.06502[2]

.08876[1] .53248[2] .25093[1]

where the Film Indices

editor looks like

Back

to top

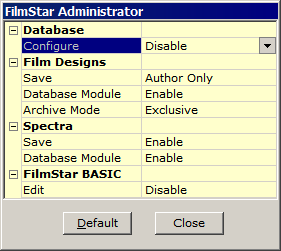

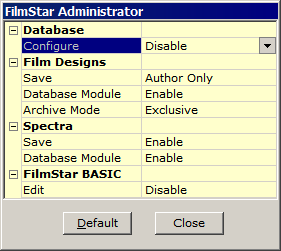

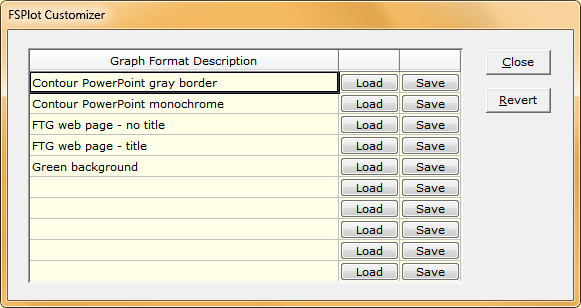

| The FilmStar

Administrator enables managers to control access to features in DESIGN,

INDEX and MEASURE. Examples: preventing QC technicians from adjusting

scan speeds, preventing optical coating technicians from modifying thin

film designs.

The Administrator

dialog is accessed in the Help menu in DESIGN and MEASURE.

Administrator status is enabled via a Security ID Module programmed

accordingly.

The 'Author Only'

setting is utilized in conjunction with NTFS

File Properties.

Please contact FTG

Software for further information.

Back to top

|

DESIGN Administrator

|

It appears the bug was introduced

in Feb or Mar 2022.

Sub Main

FileOpen "C:\Winfilm\Measure\PE-Lam9.scw"

End Sub

Fixed in 2.51.2063. If you can't

update, there's an equivalent workaround:

Sub Main

Macro "PARAMOPEN C:\Winfilm\Measure\PE-Lam9.scw"

End Sub

Need to integrate

FilmStar with Excel

or Word but have no idea what to do? Try

the following example. It will work without DESIGN being open.

In Excel access the

VBA editor (Alt+F11). Click Tools

References. You

should see FtgDesign1

listed as a Reference. Check this to add it to your

project. You will find it listed in the Object Browser with two

classes: clsBasic

and clsMain.

Now open a new module and try the following VBA program:

Sub Main()

Set dBasic = New FtgDesign1.clsBasic

Set dMain = New FtgDesign1.clsMain

k = dBasic.Macro("Fred;")

On Error Resume Next 'prevents error 440

dMain.Quit

End Sub

Now that you have a

working example, you will be inspired to Read

the Manual. Back to top

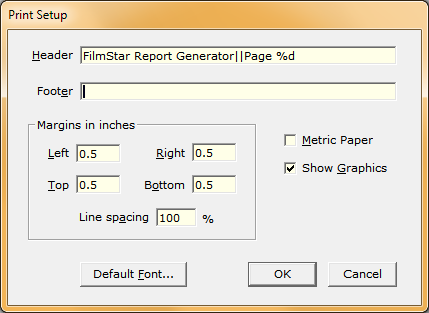

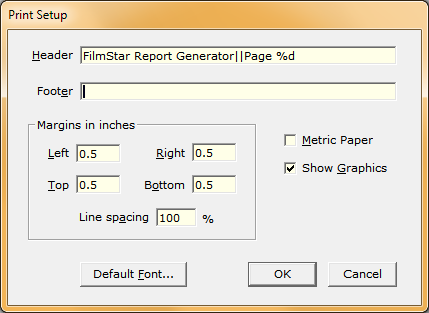

Graph not

displayed in Report Generator

A user reported that graphs

were not displayed when using template commands <<Graph>> or

<<FSPlot>>.

The problem was revealed in a screen-sharing session.

Margin values were very far off with Line spacing about

16000%.

The issue would have been impossible to resolve without

screen-sharing. |

|

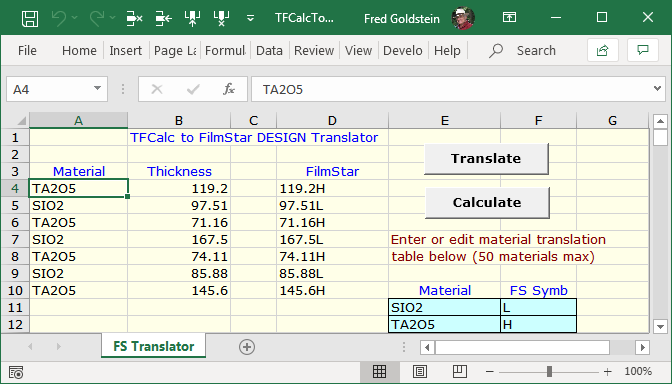

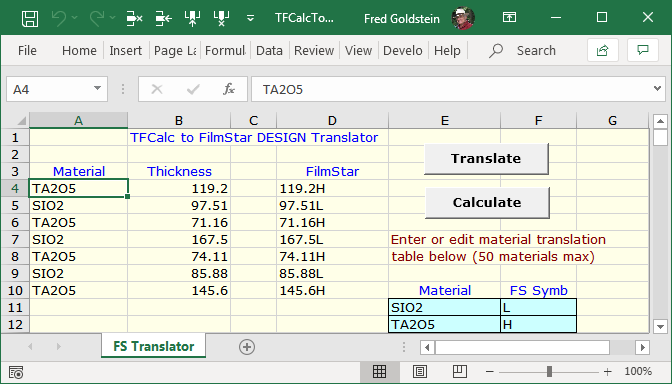

TFCalcToFS.xlsm

converts TFCalc™ designs to FilmStar format. The VBA code

is unsecured and can be modified for other thin film design

software.

Click the Translate button; a message box prompts you

to proceed or cancel. When pasted in Excel, a TFCalc design

is displayed in two columns as shown below (A & B). Next

click Calculate to plot in DESIGN.

Layer 1 (row 4) is next to the substrate (same as

FilmStar). If modifying the workbook for another design program

that might not be the case. The material

translation table (light blue cells specifies FilmStar Index

Symbols corresponding to TFCalc Material Names. Materials

import is discussed here. You

can use the same Symbol for multiple materials, e.g.

H for TiO2 & ZnS, assuming that the design does

not contain both. |

TFCalc *.mat materials files must first be converted to FilmStar *.itw

files (see

section below). Film

thickness

must be in nm; set FilmStar DESIGN accordingly in Setup Parameters.

Verify that the design is correct

by comparing results in both programs. When

comparing, be sure to

check the setting for Side 2

Compensation in Setup

Parameters. Wavelengths will not match if Inverse wavelength spacing was

selected in Graph Axes.

Excel aficionados:

DDE runs the following

macro sequence to calculate and plot the spectrum.

k& = DDEInitiate("Design1",

"Main")

DDEExecute k&,"DESIGNPASTE;AXESDRAW;CALCPLOT;"

DDETerminate k&

Unfamiliar with DDE (dynamic data exchange)?

It's a legacy Windows facility still supported and somewhat simpler to

implement than ActiveX. IsRunning("Design1.exe") ensures that DESIGN

is open.

Private Function

IsRunning%(p$)

'https://stackoverflow.com/questions/29807691...

Dim objList As Object

Set objList = GetObject("winmgmts:").ExecQuery _

("select * from win32_process where name='" & p$

& "'")

IsRunning = objList.Count

End Function

Back to top

FilmStar INDEX

BASIC programs TFCalcMatl.bas

(import single file) and

TFCalcMultMatl.bas (import multiple files) convert TFCalc™

material files (*.mat) to FilmStar n,k files (*.itw). It expects the

following format:

VERSION*1*

FORMAT*1*

POINTS*20*

DATA1*1*380.0*2.55*0.0*

DATA1*2*425.0*2.49*0.0*

DATA1*3*450.0*2.469*0.0*

Send us

samples of TFCalc .mat files which do not work properly, so that we can

modify the code

accordingly. The BASIC programs require INDEX 2.30.0201 or newer. Need help with FilmStar BASIC?

Click here for a tutorial and/or

contact FTG Software. Back

to top

PerkinElmer spectral

data files of different types (binary, ASCII, Data

Manager, PECCS) have the same .sp extension. How can the data be

utililzed in

FilmStar (Scantraq)? An easy option is to open the file in

UvWinLab and

re-store as J-CAMP (.dx extension) which can directly be opened in

FilmStar. If

this is not convenient, here are further options:

- Import binary

PECCS files via BASIC

subroutine

Sub

Pe19SpOpen

- Use programs

pe-sp1.bas, pe-sp2.bas (basic32.zip)

to import .sp ASCII files

- Convert .sp file

to J-CAMP (.dx) with PE

program pecnvrt.exe

The last choice can

convert multiple files. Copy the program to c:\uvwinlab.

New files are created in c:\uvwinlab\convert. Back to

top

|

|

The number of

built-in

dispersive Index Functions in DESIGN and INDEX was

extended in DESIGN 2.23.6001 and INDEX 2.23.2001. Not familiar with

Index

Functions? You begin in INDEX by fitting continuous dispersion

functions to n,k vs. wavelength data. Functions are then adjusted in

DESIGN

where further fitting explains differences between calculated and

measured

spectra.

Index

Tables (*.itw) stored with INDEX 2.23.2001

and newer will

be incompatible with earlier versions of DESIGN and INDEX.

1. Open INDEX and

click Functions...Built-in.

The functions which are

initially checked are those defined in previous versions of DESIGN and

INDEX. New functions are CYGEN, CYGENK2, SELL1, SELL1K1, SELL1K2,

SELL2, SELL2K1

and SELL2K2. As you scroll through the grid, note that equations are

displayed at the bottom. Consult these carefully if copying results

from

elsewhere.

|

Examples of Index

Functions based on TiO2 data sets will be found in

subdirectory c:\winfilm\index\functions. Start FilmStar INDEX and

temporarily

switch to this directory in File...Configuration...Directories

(remember

to switch back later). Open a file. Click Functions...Plot

to visually see the fit and Functions...Fit

Coefficients to review

numeric values. If you open an Index Table in INDEX (or FILM Archive

file in

DESIGN) which references a function not currently in the list of

built-ins, that

function is automatically added.

2. In DESIGN, the same

list of built-in functions will be found in the Film

Indices editor under Edit...Built-in

Functions.

3. Initial estimates

for highly nonlinear functions CYGEN and CYGENK2 may be

especially elusive. Depending on your data, there could be multiple

solutions

providing equally good fits. If you have difficulties with these or

with other built-in

or user-defined functions, send us your n,k tables (*.itw or Excel

format) as

e-mail attachments. Thanks to Steve Tuenge for suggesting function

CYGEN (Generalized Cauchy) which he has found very useful over the

years.

4. File and Edit menus

have been added to the User Index Function dialog. These include

facilities to load and save

Function Collections (*.itf) (see c:\winfilm\index\examples.itf). Note

that a

Function Collection is actually the [UserIndex] section of

c:\windows\design1.ini. An important use is transferring Index

Functions to

other users.

Be

sure to backup (save as a Function

Collection) any functions

that you are using before opening a new Function Collection.

The Edit menu lets you

delete functions and alphabetize function names.

5. File aconst.itw can

be used to test the following Index Functions included

in examples.itf: ACONFM

(uses formula), ACONVB

(uses FilmStar

BASIC program aconst.bas), ACONWS

(uses FilmStar Workbook indxfnc.vts), ACONXL

(uses Excel indxfnc.xls via DDE). Back to top

IndexSolve.bas

(in

c:\winfilm\basic32) creates index tables from

multiple spectra via DESIGN's DLS refinement algorithm.The tables is

then pasted into INDEX. As an example, we

simulated measured spectra of 50 nm Ag on

1.52 substrate at 6 degrees and 45 degrees P and S polarization.

Relevant FILM

Archive and sample files are found in indexsolve.zip.

Copy FILM

Archive

files to c:\winfilm\designs and spectral data

to c:\winfilm\spectra. IndexSolve1.faw creates spectral files and

IndexSolve2.faw is utilized when running IndexSolve.bas. Once it is

determined

that IndexSolve.bas works as expected, it is most instructive to repeat

the

calculations with spectral noise added. This is accomplished via

FilmStar BASIC

program AddNoise.bas. Back

to top

The following FilmStar

BASIC code generates an index (n, k) vs wavelength table and

copies it to the clipboard. Back to top

Sub Main

Dim w!, xn!, xk!, s$

Row% = 4 ' Row in

Film Indices dialog

For w = 400 To 700 Step 10

GetIndex Row, w, xn, xk

s$ = s & CStr(w) & vbTab & CStr(xn) &

vbTab & CStr(xk) & vbCrLf

Next w

Clipboard s

End Sub

Invalid

license type error

Reinstall

FilmStar to eliminate the (Jan/Feb 2021) error. If that is not

possible (passwords out-of-date), try this quick fix (hopefully

permanent) in

C:\Winfilm\Config\common.ini. Contact FTG Software if that

doesn't work.

[Install]

License=USB

Back to top

Invalid procedure call or argument (INDEX Calculate n,k

dialog)

Bu default, INDEX 2.51.0524 reviews spectral

data before calculating n,k in order to prevent the Invalid

procedure... message triggered by invalid data: %R

or %T < 0, %R + %T > 100%. While this prevents common errors

it does not guarantee that data are otherwise valid. The feature can

be disabled in Solve...Spectrum Type

Back to top

We suspect there are

firmware discrepancies in these instruments. If

your Lambda 40 (or similar) times out during background correction, try

adding

the following line under [Configuration] in

c:\winfilm\config\measure.ini

or c:\scantraq\config\scantraq.ini

Exit and restart

before testing.

[Configuration]

Lam40AZSCStatus=2

If your Lambda 2 or 20

(or similar) times out during background correction, try

the following line:

Lam40AZSCStatus=1

Please contact

us about this. Back to top

Expert mode OFF

automatically selects common beam filters as shown below (default mode

for PE UVWinLab).

PE Lambda 900

Index

Filter Wave

Type

1

10

3350 T-LPQ-2.5

2

9 2620.8

T-LPQ-1.5

3

8 1670.4

T-LPQ-1.0

4

7 1190.4

RG780

5

6

810.4 RG665

6

5

690.4 OG550

7

4

562.4 BG38

8

3

379.2 UG11

9

2

319.2 T=100% (no filter)

10

1

150 Glass

PE

Lambda 800

Index

Filter Wave

Type

1

7

950 RG780

2

6

810.4 RG665

3

5

690.4 OG550

4

4

562.4 BG38

5

3

379.2 UG11

6

2

319.2 T=100% (no filter)

7

1

150 Glass

Expert Mode OFF is

equivalent to Expert Mode ON with the default filter program built into

MEASURE (Scantraq). Note that Expert Mode ON is now required for

selecting a single filter for the entire scan (not

recommended). Back

to top

A user reported Error -241 "Hardware missing" after PerkinElmer

replaced a board in his

Lambda 900. The error is spurious (PE bug?) and, by default, ignored in MEASURE

2.51.1861 and newer.

In the unlikely event that the error arises from a different cause

requiring the scan to abort, enter the following under [Configuration] in Measure.ini or

Scantraq.ini:

[Configuration]

AbortOnErrN241=-1

Back

to top

Lambda

Server error (950/1050)

A user reported Lambda Server

error: Could not connect to instrument - Object variable or With

block variable not set. The problem followed network security

updates when IT failed to restore the necessary user-permissions.

Restoring permissions resolved the issue. This problem can arise in

Mpe950.exe and Mpe1050.exe which both utilize MSLambdaServer.exe.

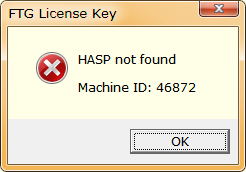

New computers lack the LPT

(parallel) printer port and cannot read HASP LPT keys. Since adding

an

adapter card does not work, keys must be exchanged for USB

types. Pricing is nominal, but current support is required.

After installing and testing new

keys, do not

return old keys! Please e-mail a photo of the destroyed key(s).

We suggest squeezing the plug with pliers as in the above picture.

The same applies to damaged USB keys. If damage is not obvious,

squeeze or break off the metal section with pliers. USB keys may be

damaged when not removed from laptops. If you tend to forget about

the attached key, check USB key shut-down warning in DESIGN

File.. Configuration.. Security.

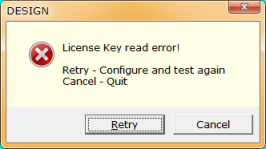

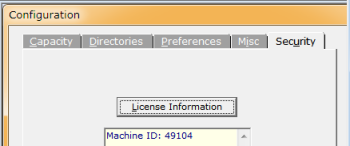

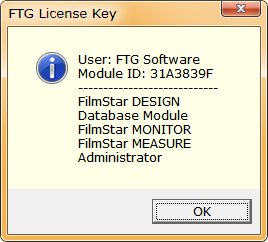

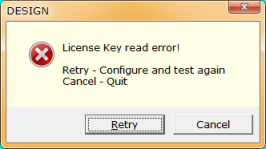

We can quickly supply a temporary software-based license

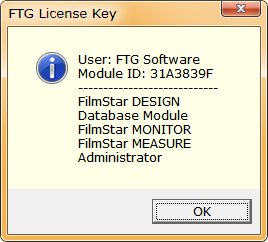

while you wait for your new USB license key to arrive. Click

Retry <License Information> and provide us with your

Machine ID.

We can quickly supply a temporary software-based license

while you wait for your USB license key to arrive. Click

Retry <License Information> and provide us with your

Machine ID.

The Machine ID is also displayed in Excel workbook

HaspTest32S.xlsm:

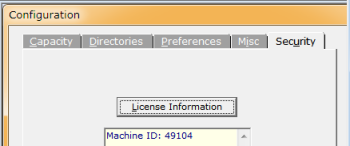

|

Hasp found

|

Hasp not found |

Back to top

Log

files

(MEASURE/Scantraq)

A running log of

input/output activity can help us debug problems in data

acquisition. A log file is enabled by adding a line similar to the

following

under [Files] in

c:\winfilm\config\measure.ini

or c:\scantraq\config\scantraq.ini

[Files]

IOLog=c:\winfilm\cary500.log (or c:\scantraq\cary500.log)

This adds a new Test

menu to MEASURE/Scantraq

containing item I/O Log Open.

When this item is checked instrument commands and responses are stored

in the

specified file. Since new data is appended, the file can be used

repeatedly. Uncheck to close and disable the log file. E-mail

the file to us for analysis and

add the exact wording of any error messages.

When no longer

required, the Test menu is removed by deleting the IOLog entry, or

(preferably, since you might need it again) by commenting it out by

prefixing the entry with a semicolon, that

is ";IOLog= etc". Back

to top

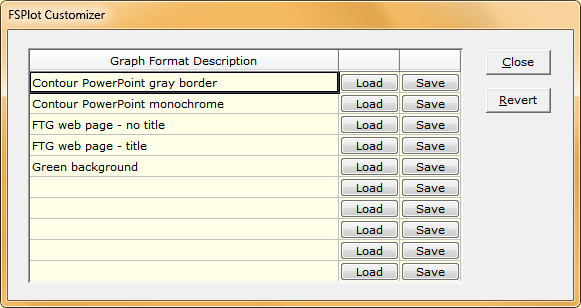

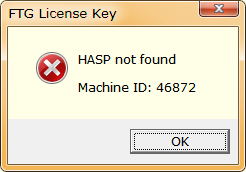

A bug has been found relating to

MEASURE format settings. Really minor, but potentially puzzling. It

mostly affects the few users who take advantage of FSPlot

File..Customize in FSPlot whereby you save and recall graph format,

say for PowerPoint, web pages, etc.

BUG: Entries that should

have been saved in ..\Winfilm\Config\Common.ini were saved in

..\Windows\Win.ini. By saving in Common.ini you have common formats

in DESIGN and MEASURE. The bug was fixed in MEASURE 2.51.1930 (30

Oct 2018).

Repair: Edit ..Windows\win.ini (Notepad) and transfer the

following sections to ..Winfilm\Config\Common.ini

[Collector]

...

[Interface]

...

[GridEnhColors]

...

[PlotModule]

...

[Spectrum2000]

; Probably no one is still using this ancient FTIR

...

Complication: If DESIGN is

on the same computer, add any [PlotModule] entries to the ones

already there. These correspond to the screen image above:

FormatR=PlotConfig 8742977,

332128, 0|PlotSize...

Format0=Contour PowerPoint gray border\\PlotConfig...

Format1=Contour PowerPoint monochrome\\PlotConfig 8458449...

Format2=FTG web page - no title\\PlotConfig 8461521, 2128...

Format3=FTG web page - title\\PlotConfig 9265225, 102128...

...

Format9=

In this case where DESIGN and

MEASURE are on the same computer, the first two entries refer to

DESIGN; the remainder to DESIGN and MEASURE.

DESIGN handles mixed

materials via User Index Function Mixed.

Here a

formula expresses the final index as a function of constituent

dispersive

indices. A linear mixing model would be expressed as

n = A*N1+(1-A)*N2

k = A*K1+(1-A)*K2

where N1, K1 are

indices for material 1 and N2, K2 are indices for material

2. Here A

is the mixing fraction (which can be treated as an optimization

variable). Calculated results for TiO2+Ti are illustrated below. Please

note

that no claim is being made that a linear model is realistic; more

complex

relationships are easily programmed.

Porous TiO2

films with

packing density < 1 can be simulated by mixing

film materials with

material Void,

where Void is an index table containing values 200 nm, n =

1.0; 1000 nm, n = 1.0; 5000 nm, n = 1.0. Users should verify that

results are

reasonable; the following program illustrates a

method for viewing index values.

Sub Main

Dim fmt$, w!, xn!, xk!

Const f$ = "0.00000" ' Format

For w = 400 To 800 Step 50

GetIndex 3, w, xn, xk ' Material 3 (first film) in

' Film Indices editor

Debug.Print CStr(w) & ", " & Format(xn,f$) & ",

" & Format(xk,f$)

Next w

End Sub

Back to

top

If you find the mouse

pointer disappearing in the main graphics window, try setting Control

Panel.. Mouse Properties.. Pointers to a different scheme. We recommend

Windows Inverted which, in our opinion, offers the best contrast no

matter what the background. Back

to

top

At first it appears

that there is no way to use OCXs (ActiveX components) in FilmStar

BASIC. While you cannot add a component to the BASIC UserDialog Editor,

you may be able

to use the OCX as an object.

This is illustrated in the following code snippet

which records temperature from an Omega DPi32 thermometer. The ActiveX

module

iSeries10.ocx is provided by the manufacturer.

Sub Main

' IMPORTANT: be sure to add reference to

iSeries10.ocx

Dim iDevice As Object

' Found the object name in the Registry

Editor

Set iDevice = CreateObject("iSeriesAlpha10.iDevice")

With iDevice

.ServerCommPort=1

'

set COM port

Debug.Print .LastData ' read thermometer

End With

Set iDevice = Nothing

End Sub

That's all there is to

it. You do, of course, lose any graphics provided by

the OCX, but very often you really don't need that anyway. Back to top

When measuring

reflectance your Baseline scan attempts to compensate for the

reflectance attachment. Typically the scan is performed with no optic

(or a 'black sample') on the attachment. WHAT

YOU DON'T WANT TO DO is check 'Block sample beam during Baseline scan' (or

similar label in older versions).

This option can be found in PE 983, PE Lambda 800-1050 Scan Method

dialogs and is generally intended for transmittance measurements.

|

ZOOM allows us to view your computer. This is often

the fastest way to

resolve issues, and very often the ONLY way. |

We solve

problems by reproducing them with data files sent to

us as e-mail attachments. The body of the e-mail should also include a

clear statement of

the problem, exact wording of

error messages, etc. Users with expired annual support may be required

to renew.

DESIGN...Enable FILM Archive Mode (File Menu) so

that designs and parameters are stored in one file (*.faw,

c:\winfilm\designs). Attach the file to your e-mail. There are two

choices if your design includes dispersive materials:

1a. Attach ALL index

tables referenced in Film Indices (*.itw, c:\winfilm\index). If the

problem can be reproduced with constant indices there is no need to

attach index tables. Attach

all tables (*.itw) listed in Setup.. Film Indices, even

if not used in the design. (Simplify by first deleting unused

material names.)

1b. Recommended alterative: if

using

only dispersion tables (not dispersive functions such as

Sellmeier and Cauchy), enable Archive n,k Data

(File Menu) which embeds dispersion data in the FILM Archive

file.

THIS IS THE BEST WAY TO DEAL WITH DISPERSION.

2. If using a

Wavelength List (*.wls) or Wave/Angle List (*.wal) add that as well. As

an alternative to a Wavelength List (often used with CIE data),

consider using Wavelength Range instead.

3. If you have Subscript

out of range errors it is likely

that you need to increase values in File.. Configuration.. Capacity.

These values are stored in ..\Winfilm\Design1.ini which you could

attach to your e-mail.

MONITOR...Upon exiting MONITOR or clicking File...Save

All four work.* files are

stored in c:\winfilm\monitor. Attach these files zipped into one file.

Add index tables referenced in Film Indices.

Alternatively attach

the four files referenced in File...Save

As. The FILM or FILM Archive

file is stored in c:\winfilm\designs and the other three files are in

c:\winfilm\monitor.

BASIC...Attach a short code snippet showing your problem. Isolate the

problem in the simplest code possible.

Long complex programs may entail extra charges.

Spectra...Attach any spectral data files being

utilized in DESIGN or INDEX. Or send an Excel .xls file (zipped please)

with data pasted therein. If you don't have FilmStar MEASURE, there are a number of options

to create data files. See the winfilm\basic32 directory for support for

Shimadzu and other spectrophotometers.

Excel...Problems in running FilmStar (server) from Excel (client) or

vice-versa cannot be analyzed with "it doesn't work." Please

attach the Excel file (.xls or .xlsm) and any FilmStar files

required for us to reproduce the problem. VBA code copied and

pasted into your e-mail is insufficient! The amount of help

provided as part of annual support is at our discretion. This

may be useful: Excel (as

Client) Reliability.

Please include program

version number. This is found by clicking

Help...About. If the program absolutely does not open at all, you can

get the

version number by right clicking the file name in Windows Explorer.

Users

occasionally report problems that are already fixed. Before contacting

us, consult the FilmStar Revisions

History page to

determine whether a newer release fixes the problem.

In some cases it is

useful to attach screen images.

This is accomplished as follows:

- Copy the active window

to the clipboard with <Alt+PrtScr>

(<PrtScr> by itself copies the entire screen.)

- Paste into a graphics

program which can store in GIF or PNG format.

- A recommended alternative is to

paste images into a Word or Excel attachment; several images can be pasted into a single document.

- Do

not send graphics

in .bmp format! Back to

top

You need to supply QA data in Excel

format and have developed a workbook for the purpose. When you

re-save the workbook it includes VBA code as well as extraneous

worksheets. What you really need to do is save data only as an Excel

workbook without your proprietary VBA code. Is there a way to do

this without re-saving the original workbook?

Consider workbook QAFilter.xlsm which creates two data sheets:

Spectra and Results. In the following the sheets are

selected and saved to a new macro-free XLSX file. The original

QAFilter.xlsm is unaltered and may be saved as read-only

(recommended) for further security.

Sub SaveScan(Byval PartNum$)

On Error Resume Next

Sheets(Array("Spectra", "Results")).Select

Sheets(Array("Spectra", "Results")).Copy

ActiveWorkbook.SaveAs Filename:="C:\Winfilm\Spectra\" &

PartNum$ _

& ".xlsx", FileFormat:=xlOpenXMLWorkbook,

CreateBackup:=False

ActiveWorkbook.Close SaveChanges:=False

Windows("QAFilter.xlsm").Activate

End Sub

In the case that only

one worksheet needs to be save, remove the Array statement as in

Sheets("Spectra").Select

File...Print Graphics

creates a graph in the Report Generator that is supposed to fill

the page. A user asked "Is it possible to reset the value for my Report

Template when

I am printing graphics in DESIGN? The current setting in the template

is <<Graph

83>> and I would like to have this reset to default to

<<Graph 130>>.

Any advise?"

Default relative graph

size can be changed in the Configuration dialog

Misc tab. Another approach is to use a BASIC program to set the size to

a

particular value.

Sub Main

t$ = Template

' save

current template

Template = "<<Graph

130>>"

k = Macro("ReportShow;")

Template = t$

'

restore saved template

End Sub

This can be assigned

to a macro key. Back

to top

SchottFilter.zip

(2.4M) contains the installer for the Schott filter glass program Filter

'98

that was originally available on SchottGlassTech.com.

Back to top

Subscript out of range error

This common error can usually be

fixed by increasing capacity in File..Configuration..Capacity.

The error occurs in FTIR/OOI Servers (Processed Data) when there are

excessive points in the Standard file. Fix: Using Notepad, increase

StdCapacity in ..\Winfilm\Config\FtgServer.ini as follows:

[PE Spectrum 10]

StdCapacity=10001

After restarting the error message should disappear. We recommend

Notepad++ (free) as an

alternative to Windows Notepad. Maximum capacity is 32K.

Back to top

If decommissioning an

old computer or reinstalling Windows, first copy all Winfilm (Scantraq) subdirectories to a USB memory stick. Then install FilmStar (Scantraq) on your new

computer. You next need to transfer data files and custom settings. The following assumes that FilmStar

(Scantraq) programs are located in C:\Winfilm (C:\Scantraq) on both computers; if not, adjust

paths accordingly.

-

Install

from

files/setup32.exe

or, if FilmStar support is not up-to-date, from the latest version

on your hard disk, probably in your Downloads directory. Installation

passwords are found at the bottom of the FilmStar News e-mails. If support is

not current, check old FilmStar News e-mails for passwords corresponding

to the installer's date. Installation

issues are discussed

here.

-

Copy C:\Winfilm (C:\Scantraq) subdirectories from

your old

computer to the new; do not copy programs directory

C:\Winfilm (C:\Scantraq).

-

Can't open designs

with missing n,k tables or user-defined functions? Check 'Can

open designs...' in File.. Configuration.. Preferences.

You can then import designs and later repair index values.

Note: Attach your USB Security ID Module

after installing FilmStar. This ensures that Windows

plug-and-play will find it If you have a very old copy of FilmStar you may

need to contact us. Back to top

|