|

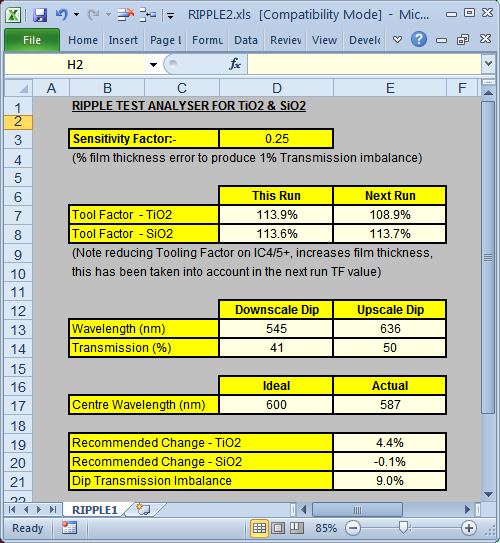

Technical Issues - Tooling Factor Correction Optical monitor tooling

(monitor/substrate M/S) can be calculated in MONITOR. One deposits a

fairly thick film, say 15 quarter waves, on a monitor glass and

subsequently measures the coated substrate in a spectrophotometer. In

former times a slide rule helped to determine the number of quarter

waves on the coated substrate. This technique, possibly developed at

Bausch & Lomb in Rochester, has stood the test of time and is widely utilized. Is the half

wave ripple design optimum for DESIGN tooling correction? How much can

thicknesses deviate before tooling correction fails? We applied our

Gedankenspektrum

technique with a FilmStar BASIC program simulating tooling deviations

from -30% to +30%. As it happens, the half wave ripple design is not

the best candidate. In initial experiments we found 1H 1L 2H 1L

1H to be somewhat superior with correct solutions for ~20% deviation in both H

and L layers.

The FilmStar BASIC program and corresponding FILM Archive file can be downloaded. As shown below, solutions are possible with fairly large thickness deviations.

|

Copyright © 2023 FTG Software Associates

Last updated on

January 31, 2023